Anyone tired adding Seafom to a tank that has been sitting for some time? Wondering if that and topping off with fresh fuel would be OK?

Remember the engine was rebuilt just prior to it sitting for this project.

Long-Term Z Project

Apr 3, 2011, 5:16 pm

When you get settled into a place with a garage and you are on your way with funding a solid retirement plan with your emergency funds secure, you can look into getting a toy to work on. I recommend something old without all the high-tech gadgetry of todays cars. Thin start tinkering away in your spare time after doing your research.

Also, it helps to have friends to bail you out when you hit a sticky wicket. My two biggest buddies have been long-time Z friend Super Dave (not on this forum) and Larry (HoleInOne). No way I would have done any of this without their help and support. They both rock!!!

BTW, you missed a rocking Chevelle at C&C this past weekend. That shows you not to move to Boston.

Also, it helps to have friends to bail you out when you hit a sticky wicket. My two biggest buddies have been long-time Z friend Super Dave (not on this forum) and Larry (HoleInOne). No way I would have done any of this without their help and support. They both rock!!!

BTW, you missed a rocking Chevelle at C&C this past weekend. That shows you not to move to Boston.

1983 Datsun 280ZXTurbo

Apr 5, 2011, 4:31 am

A couple of more small parts ordered today to finish off the IC pipe reroute. Hope to have them before the weekend.

Still need to sort out my other spacing issue with the vacuum line bungs needing to be moved. Really bummed about this one since the welds were all finished on a pretty SS pipe that is most likely now waste.

Still need to sort out my other spacing issue with the vacuum line bungs needing to be moved. Really bummed about this one since the welds were all finished on a pretty SS pipe that is most likely now waste.

1983 Datsun 280ZXTurbo

Apr 7, 2011, 5:12 pm

Last few pieces to reroute the IC piping arrived today.

My to-do-list is getting very short.

just need to sort out my spacing issue in regards to the AFM to turbo boot where I needed to shorten a tube and move a bung. Once that is done, I charge the battery, drain the gas tank, and fire it up.

So very close....

My to-do-list is getting very short.

just need to sort out my spacing issue in regards to the AFM to turbo boot where I needed to shorten a tube and move a bung. Once that is done, I charge the battery, drain the gas tank, and fire it up.

So very close....

1983 Datsun 280ZXTurbo

Apr 13, 2011, 3:51 pm

New Griot's Garage catalog came today with a grey 280Z Turbo on the cover.

2006 Time Magazine's "Man Of The Year"

Apr 13, 2011, 6:01 pm

Time for more pics and update.

Outside of attaching a heat shield under the hood and charging the battery, I could officially close the hood and call that portion done.

All the plumbing I needed to work out is finished and installed. Here's some pics:

Here's the downpipe with the O2 installed. You can see where the stainless braided oil feed line attaches to the turbo via an -AN fitting. You can also see on the left side of the downpipe, the plug attached where the future wideband O2 sensor will go.

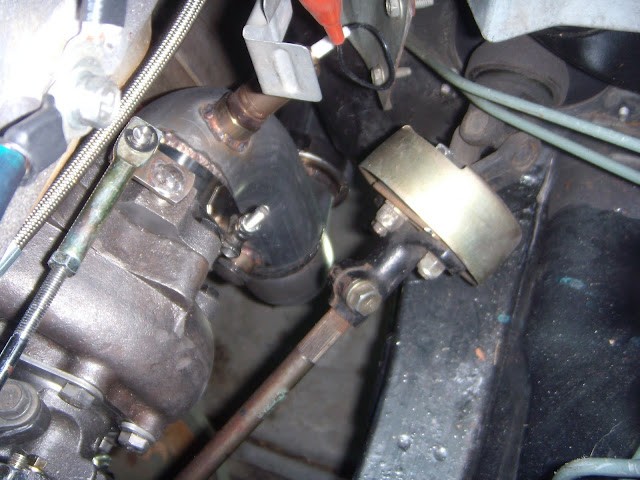

This is the block-off plate where I removed the EGR valve. I also removed the Vacuum Control Module and bypassed it via a fitting directly from the air feed after the air flow meter to the ACC valve that handles the engine idle.

The next pics show the intercooler (IC) piping that leads from the turbo to the IC. The hump connectors can accommodate the rocking of the motor and prevent the piping from coming apart.

After I got the IC pipe above installed, I needed to attach the Air flow Meter to the turbo inlet. I needed to accomodate three vacuum lines in this. One feeds the ACC valve that handles idle, a second attaches to the valve cover, and the third goes to the fuel charcoal cannister. The first pic shows the 3" stainless pipe with fittings welded in place. these can later be plugged when I replace the stock electronic Computer unit with a custom MegaSquirt & Spark engine management system.

Tomorrow, I hope to install the 3" mandrel exhaust, which is completed, just needs to be bolted into place. After that, just recharge the battery and turn the key.

Outside of attaching a heat shield under the hood and charging the battery, I could officially close the hood and call that portion done.

All the plumbing I needed to work out is finished and installed. Here's some pics:

Here's the downpipe with the O2 installed. You can see where the stainless braided oil feed line attaches to the turbo via an -AN fitting. You can also see on the left side of the downpipe, the plug attached where the future wideband O2 sensor will go.

This is the block-off plate where I removed the EGR valve. I also removed the Vacuum Control Module and bypassed it via a fitting directly from the air feed after the air flow meter to the ACC valve that handles the engine idle.

The next pics show the intercooler (IC) piping that leads from the turbo to the IC. The hump connectors can accommodate the rocking of the motor and prevent the piping from coming apart.

After I got the IC pipe above installed, I needed to attach the Air flow Meter to the turbo inlet. I needed to accomodate three vacuum lines in this. One feeds the ACC valve that handles idle, a second attaches to the valve cover, and the third goes to the fuel charcoal cannister. The first pic shows the 3" stainless pipe with fittings welded in place. these can later be plugged when I replace the stock electronic Computer unit with a custom MegaSquirt & Spark engine management system.

Tomorrow, I hope to install the 3" mandrel exhaust, which is completed, just needs to be bolted into place. After that, just recharge the battery and turn the key.

1983 Datsun 280ZXTurbo

Apr 14, 2011, 6:21 am

Almost to the final installment of this thread. Put the exhaust in this AM. Here're the pics:

Downpipe from above, but you ca see the exhaust connected to it in this one.

and from below

The center section where the CAT would normally live. Looking toward rear of car.

Center section looking back toward front. I was holding off welding on hangers for this until I knew it all lined up perfectly, so ignore the t-bolt clamp holding it to the brackets. Minor detail at this point.

Rear section. This was part of my 3" CAT back set-up where I paid a "professional". Personally, I think the part I did came out a heck of a lot nicer and for less $$$.

And finally a shot from the back. The exhaust is hanging straight and level. Whew...

Final step is to recharge the battery and decide if I'm going to drain the tank after sitting since June 2009, or roll the dice and hope all is well with the fuel. I was bummed to find that the ZXT tank doesn't have a drain plug on it. I really don't want to drop the tank. I need to get the battery charged to see how much fuel is still in the tank, then decide what to do.

Downpipe from above, but you ca see the exhaust connected to it in this one.

and from below

The center section where the CAT would normally live. Looking toward rear of car.

Center section looking back toward front. I was holding off welding on hangers for this until I knew it all lined up perfectly, so ignore the t-bolt clamp holding it to the brackets. Minor detail at this point.

Rear section. This was part of my 3" CAT back set-up where I paid a "professional". Personally, I think the part I did came out a heck of a lot nicer and for less $$$.

And finally a shot from the back. The exhaust is hanging straight and level. Whew...

Final step is to recharge the battery and decide if I'm going to drain the tank after sitting since June 2009, or roll the dice and hope all is well with the fuel. I was bummed to find that the ZXT tank doesn't have a drain plug on it. I really don't want to drop the tank. I need to get the battery charged to see how much fuel is still in the tank, then decide what to do.

1983 Datsun 280ZXTurbo

Apr 14, 2011, 6:39 am

Anyone tired adding Seafom to a tank that has been sitting for some time? Wondering if that and topping off with fresh fuel would be OK?

Remember the engine was rebuilt just prior to it sitting for this project.

Remember the engine was rebuilt just prior to it sitting for this project.

1983 Datsun 280ZXTurbo

Apr 14, 2011, 10:49 am

Sounds like lawnmower gas by now.

2006 Time Magazine's "Man Of The Year"

Apr 14, 2011, 4:30 pm

fuck this thing is taking forever

and drain the tank, no seafoam...why would you seafoam a rebuilt engine?? let the seals seat

and drain the tank, no seafoam...why would you seafoam a rebuilt engine?? let the seals seat

the Sledgehammer

2001 Lamborghini Diablo 6.0 - Baby Huey!!! <3

2004 Porsche Carrera GT -Terrorizing society since Oct 16 '09 - DEAD

2001 Acura NSX -SOLD-

2001 Lamborghini Diablo 6.0 - Baby Huey!!! <3

2004 Porsche Carrera GT -Terrorizing society since Oct 16 '09 - DEAD

2001 Acura NSX -SOLD-

Apr 14, 2011, 5:33 pm

Sounds like lawnmower gas by now.

agreed

I need a siphon tube now. The older Z's had a drain plug, but after crawling around under there today, turns out mine does not.

I'm really not looking forward to a mouth full of gas.

1983 Datsun 280ZXTurbo

Apr 14, 2011, 5:34 pm

fuck this thing is taking forever

yea, but its looking pretty good, huh?

1983 Datsun 280ZXTurbo

Apr 15, 2011, 1:06 am

Looking great mark. Can't wait to see you and Beth on the road again.

Apr 15, 2011, 6:01 am

Off to Lowes to get some CLEAR tubing to siphon the gas. I have an old garden hose I could use, but clear tubing will let me see the gas before I end up with a mouthful of it.

1983 Datsun 280ZXTurbo

Apr 15, 2011, 2:27 pm

This is coming out great Mark! Quite the undertaking.

Apr 15, 2011, 4:49 pm

Thanks. Its been long, fun, frustrating and very fulfilling.

1983 Datsun 280ZXTurbo

Apr 17, 2011, 5:16 pm

After a morning of TRYING to work on the truck and then the Z and failing at everything I tried, I decided the Car Gods did not want me to touch a motor vehicle today. Instead, I spent the day watching racing on TV.

Maybe Wednesday will be a car day.

Maybe Wednesday will be a car day.

1983 Datsun 280ZXTurbo

Apr 17, 2011, 5:21 pm

So how come I finally get around to removing a few minor emission pieces and the Feds and State gov'ts decide testing is a viable thing in IN? I should note, I did not get rid of the CAT. Its with the car, on the shelf beside it, keeping the car cozy and safe.

Oh well, at least I planned for this with my design. I'll just wait and see what happens before I 'adjust' to any new gov't regs.

Oh well, at least I planned for this with my design. I'll just wait and see what happens before I 'adjust' to any new gov't regs.

1983 Datsun 280ZXTurbo

Apr 18, 2011, 11:11 am

So how come I finally get around to removing a few minor emission pieces and the Feds and State gov'ts decide testing is a viable thing in IN? I should note, I did not get rid of the CAT. Its with the car, on the shelf beside it, keeping the car cozy and safe.

Oh well, at least I planned for this with my design. I'll just wait and see what happens before I 'adjust' to any new gov't regs.

Oh well, at least I planned for this with my design. I'll just wait and see what happens before I 'adjust' to any new gov't regs.

Are you saying Indiana is considering state emissions testing implementation?!?

2006 Time Magazine's "Man Of The Year"

Apr 18, 2011, 5:16 pm

Are you saying Indiana is considering state emissions testing implementation?!?

Yup.

1983 Datsun 280ZXTurbo

Apr 18, 2011, 5:17 pm

1983 Datsun 280ZXTurbo

Apr 19, 2011, 6:15 am

OBAMA!!!

arent you glad you voted for him

if you need anyone to such out the gas I can...I have experience

lol

hell I usually smell like ass, grass, and gas any ways, whats a lil fluid in my mouth gonna hurt....

and yes, those entaundras are intentual

arent you glad you voted for him

if you need anyone to such out the gas I can...I have experience

lol

hell I usually smell like ass, grass, and gas any ways, whats a lil fluid in my mouth gonna hurt....

and yes, those entaundras are intentual

the Sledgehammer

2001 Lamborghini Diablo 6.0 - Baby Huey!!! <3

2004 Porsche Carrera GT -Terrorizing society since Oct 16 '09 - DEAD

2001 Acura NSX -SOLD-

2001 Lamborghini Diablo 6.0 - Baby Huey!!! <3

2004 Porsche Carrera GT -Terrorizing society since Oct 16 '09 - DEAD

2001 Acura NSX -SOLD-

Apr 20, 2011, 9:55 am

Mark... This is awesome! What a great project! Cant wait to see the beast alive at C&C! That kind of RWHP in that small car should be an absolute blast to drive!

Apr 20, 2011, 11:52 am

Z is off the jackstands. I drove it around the block. I still need to retune the electronic boost controller.

I also need all the oily residue to burn off the new parts. Had the normal smoke after driving around the block.

I also need all the oily residue to burn off the new parts. Had the normal smoke after driving around the block.

1983 Datsun 280ZXTurbo

Apr 21, 2011, 2:20 am

Z is off the jackstands. I drove it around the block. I still need to retune the electronic boost controller.

I also need all the oily residue to burn off the new parts. Had the normal smoke after driving around the block.

I also need all the oily residue to burn off the new parts. Had the normal smoke after driving around the block.

Congrats!

2006 Time Magazine's "Man Of The Year"